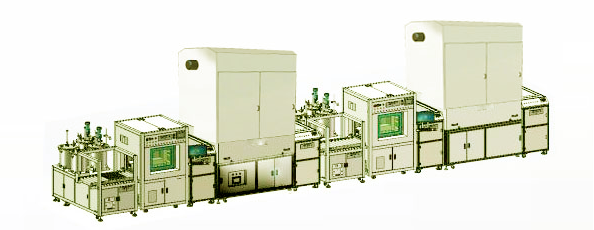

XZASM-VCO-2 film capacitor filling epoxy drying machine

Published:

2023-07-27

Function description: Suitable for automatic epoxy filling and drying of CBB61 metallized capacitor core.

Process flow: Docking pilot LD522 assembly machine finished product feeding → first gluing → into the dryer drying → second gluing → into the dryer drying → product feeding on the test

Equipment composition: automatic vacuum filling machine *2 sets, automatic vertical dryer *2 sets

The main functions of the equipment can be realized: the equipment and the pilot assembly machine automatically docking loading, the first and second epoxy automatic cycle drying, the automatic discharge and the docking work of the measuring machine

Drying time and temperature:

Drying time: 2H after first gluing, 2h after second gluing, a total of 4h;

Drying temperature 80℃±3℃ (40~150℃ can be adjusted according to your requirements)

Dryer temperature range: room temperature +15℃ ~ 150℃

Equipment working mode: After the assembly machine is discharged, it is manually or mechanically loaded into the tray → transported to the vacuum filling machine → vacuum filling machine → Automatically enter the vertical dryer after filling glue → Automatically discharge into the next cycle after 2 hours.

Overall size: L9200MM*W1550MM*H1950MM

Glue filling machine: L1200MM*W1550MM*H1500MM*2

Drying furnace: L2200 MM* W1550 MM*H1950 MM*2(reference size)

Vacuum filling machine: L1200MM*W1250MM*H1500MM

Previous:

Relevant Case